Anping Yuanfengrun Mesh Products Co., Ltd.

Qijie's parent company Anping Shenghe Metal Wire Mesh MFG Co., Ltd

was set up in 1999. It is located in Anping, which has a reputation

of "home of wire mesh" in China. Qijie is particularly established

for export by Shenghe. The company implements "one team, two

brands" management system and development strategy! We are a

leading enterprise in this line with a registered capital of

500,000 US dollars, covering 40,000 square meters, has 3 plant

areas, 30 stainless steel woven mesh machines, 18 welded wire mesh

machines, 8 cutting and flattening mesh machines, and 2 automatic

PVC coating lines, with annual amount of more than $ 20 million.

The main products are stainless steel insect mesh, fence panels,

chain link fence, gabion baskets, woven screening mesh, welded wire

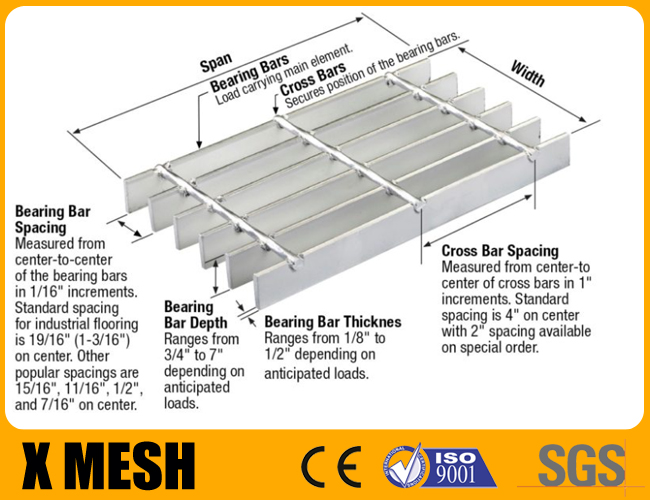

mesh, expanded metal mesh, perforated metal and various wire

products. Our main aim is to ensure customer satisfaction by

providing superior quality products at reasonable prices. We use

meticulous quality control procedures and analysis in order to

ensure our products meet the international standards. A combination

of competitive prices, on-time delivery and quality guarantee will

make us our customer's best choice.